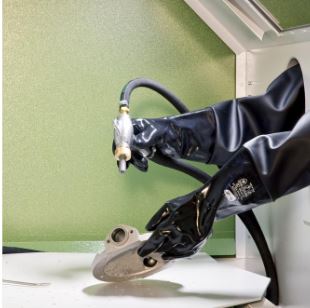

SAND BLASTER GUN – USE ON METALS

For some years now, this tool has been part of our machine park and is widely used for cleaning mechanical parts.

In metal cleaning processes, sandblasting is widely used, as there are many advantages compared to cleaning with traditional abrasives such as brushes, discs, and sandpaper.

- The first advantage is the ability to reach the entire surface, including corners, edges, and grooves.

- Thanks to the immediate visual control of the treated surface, it is possible to obtain a homogeneous and uniform result.

- With sandblasting, all types of metals can be worked on.

Sandblasting is a surface preparation method that is used for metals to:

- remove rust;

- remove grease smudges and paint residues;

- repair and maintain molds for sheet metal or casting processes.

In general, sandblasting is used to clean surfaces and bring them back to their original state before proceeding with new processing phases, such as welding and painting.